Abstract

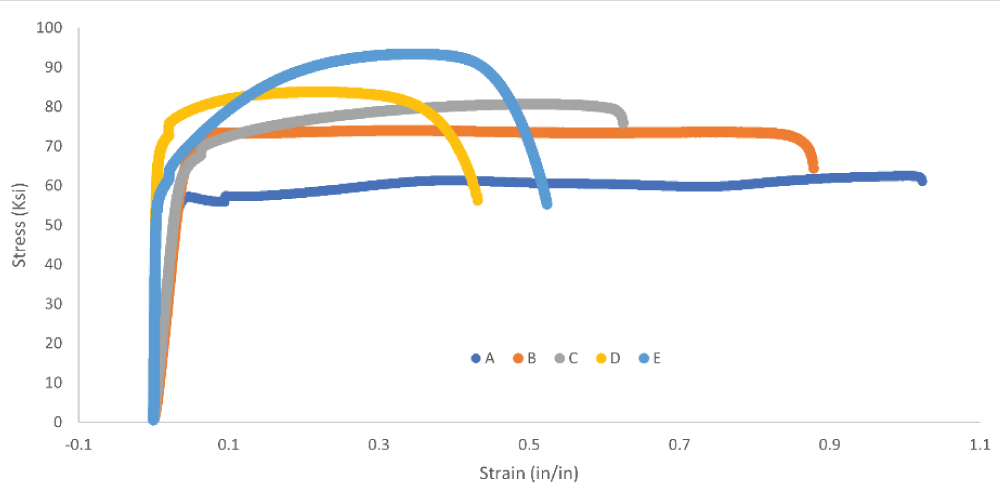

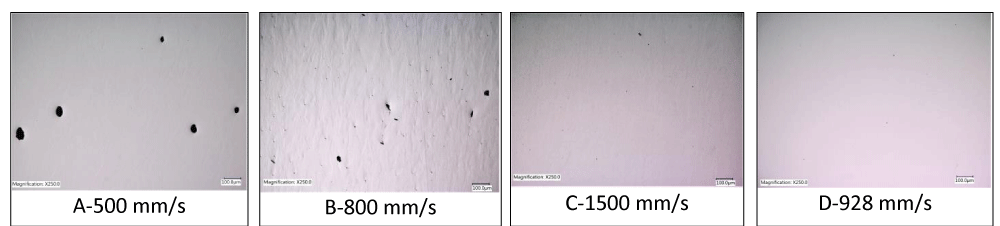

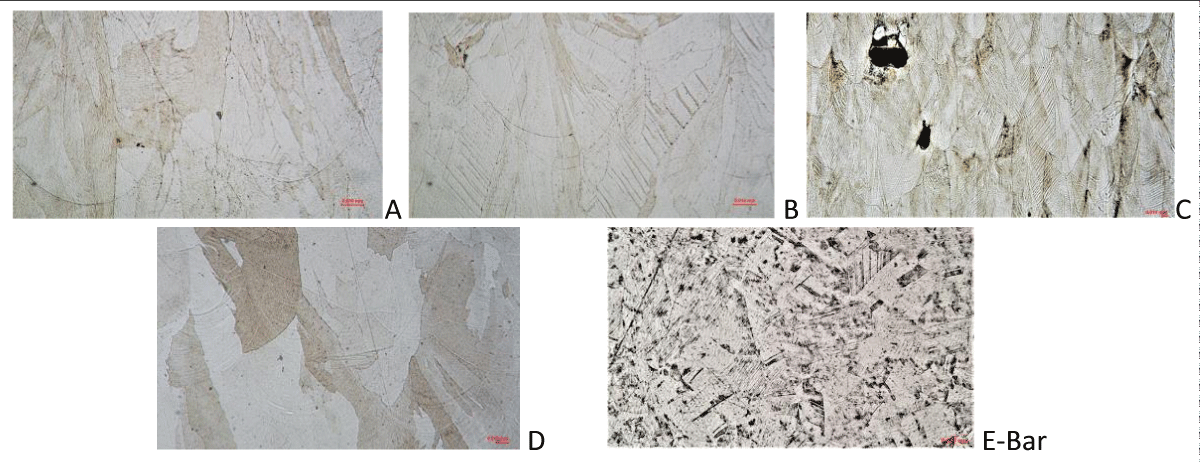

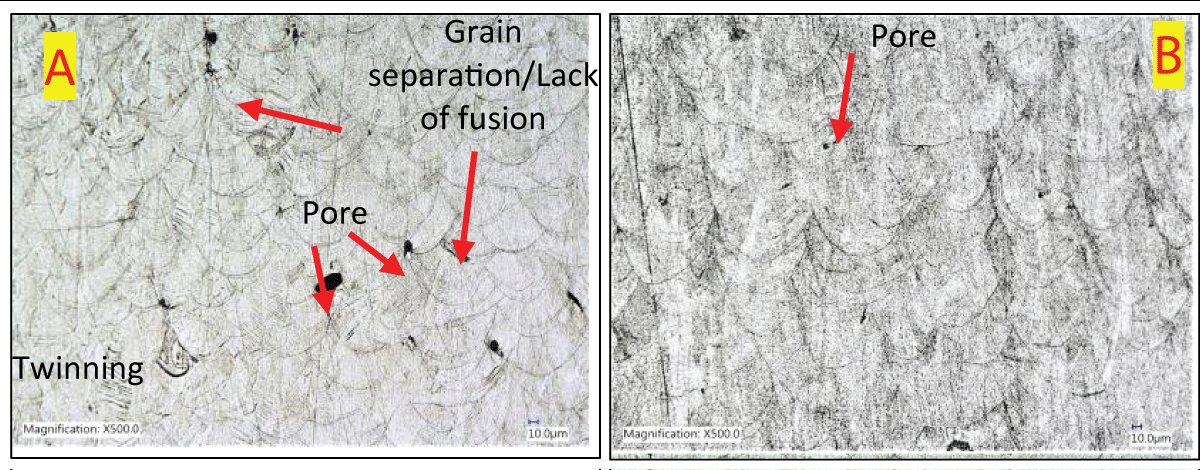

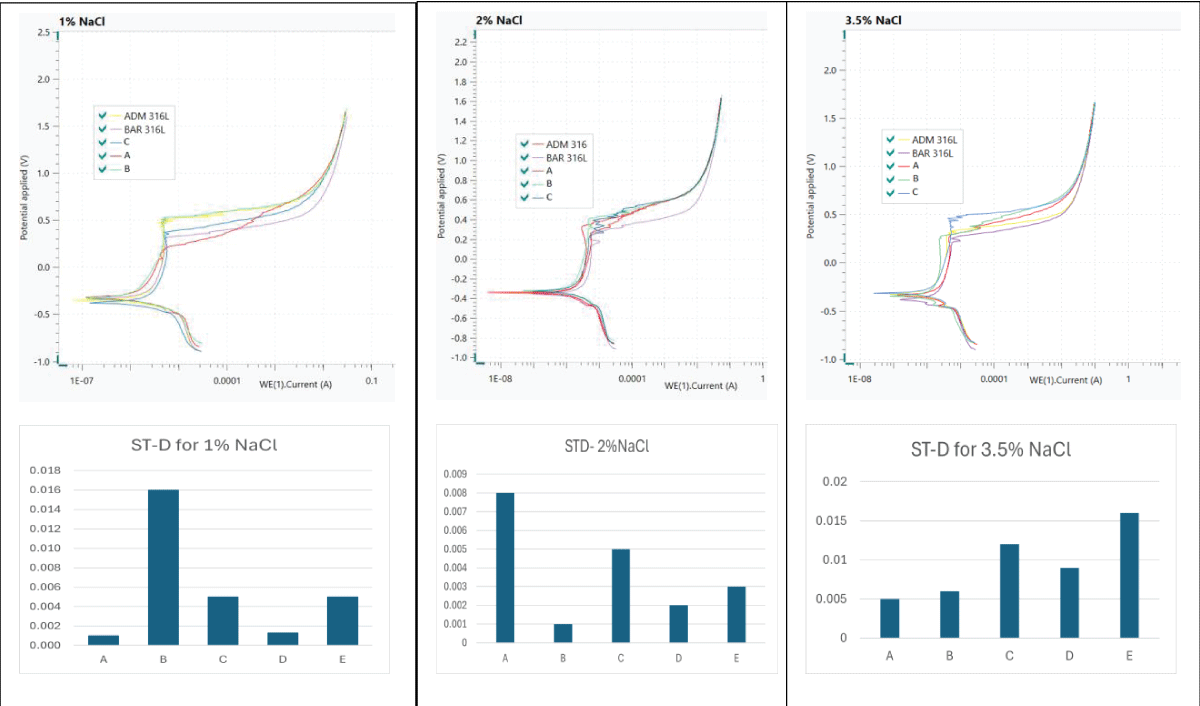

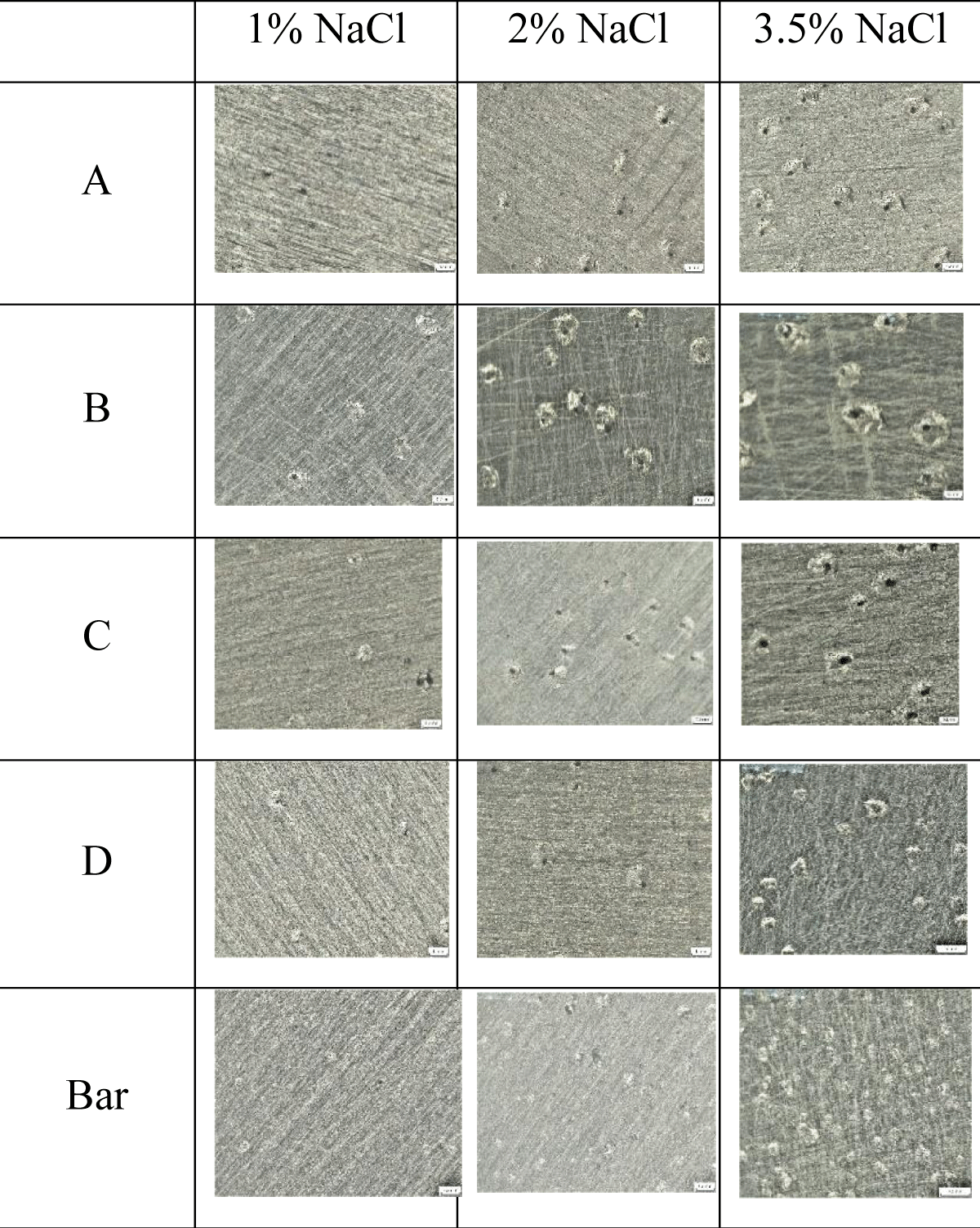

Laser Bed Powder Fusion (LBPF) has significantly simplified and accelerated solving complex design challenges, owing to the design flexibility it introduces to additive manufacturing. This technology enables the creation of innovative structures and intricate geometries in a single processing step, in contrast to conventional manufacturing techniques that necessitate multiple stages. Consequently, LBPF lowers production costs, shortens time to market, and enhances the rapid replenishment of stock components. To assess and validate the additive manufacturing process across various applications, it is essential to examine the mechanical, microstructural, and, in certain instances, corrosion characteristics of the materials. The impact of different additive manufacturing laser printing parameters with the goal of enhancing production speed and the quality of parts fabricated from 316L stainless steel, while maintaining mechanical properties and corrosion resistance, was analyzed. This involves selectively adjusting parameters such as laser power, hatch spacing, and laser speed for 20-micron layers that were compared to our standard 40-micron layer parameters. Additionally, evaluations of metallurgical, mechanical, and electrochemical potentiodynamic (corrosion) properties are conducted.